Our Products

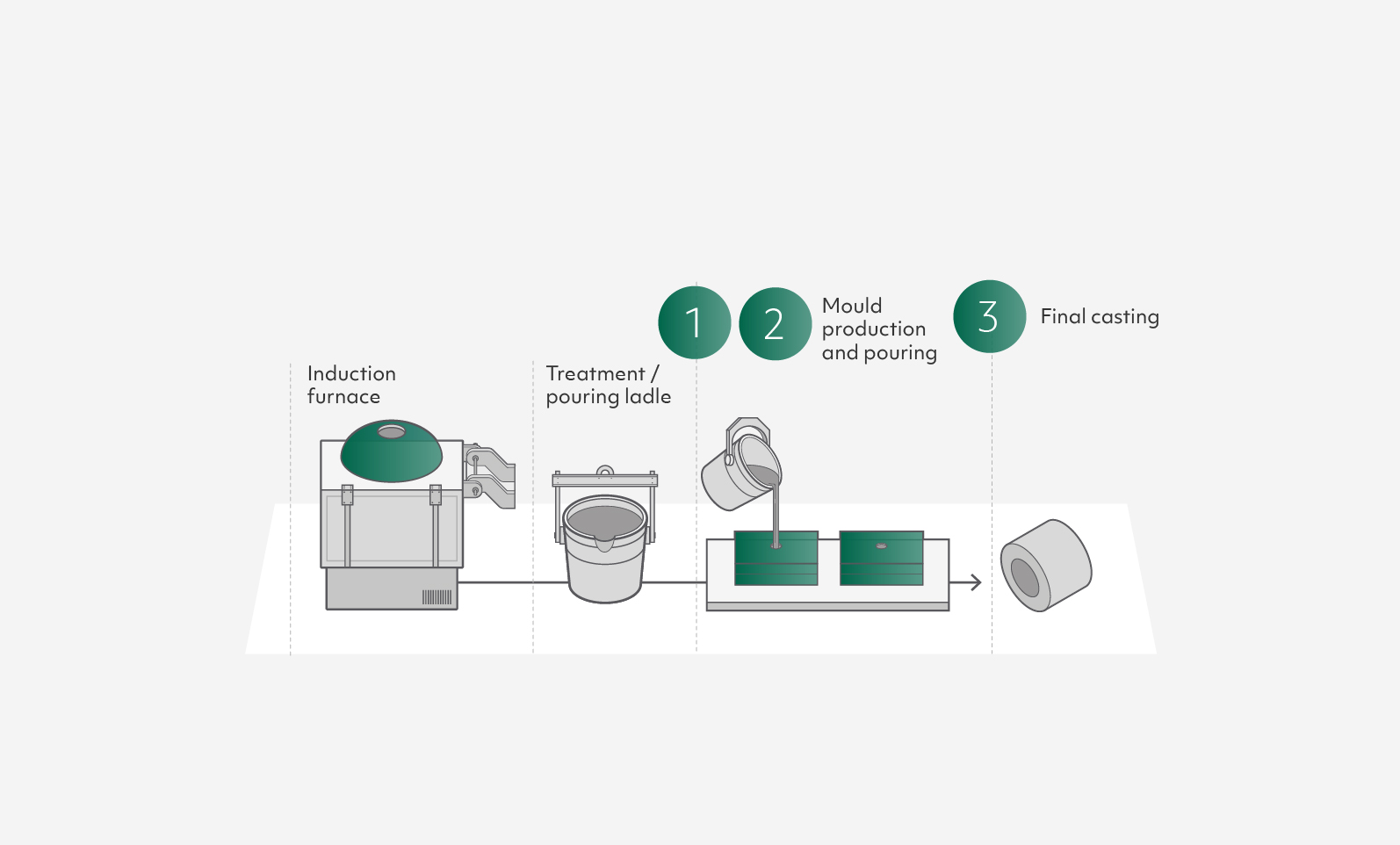

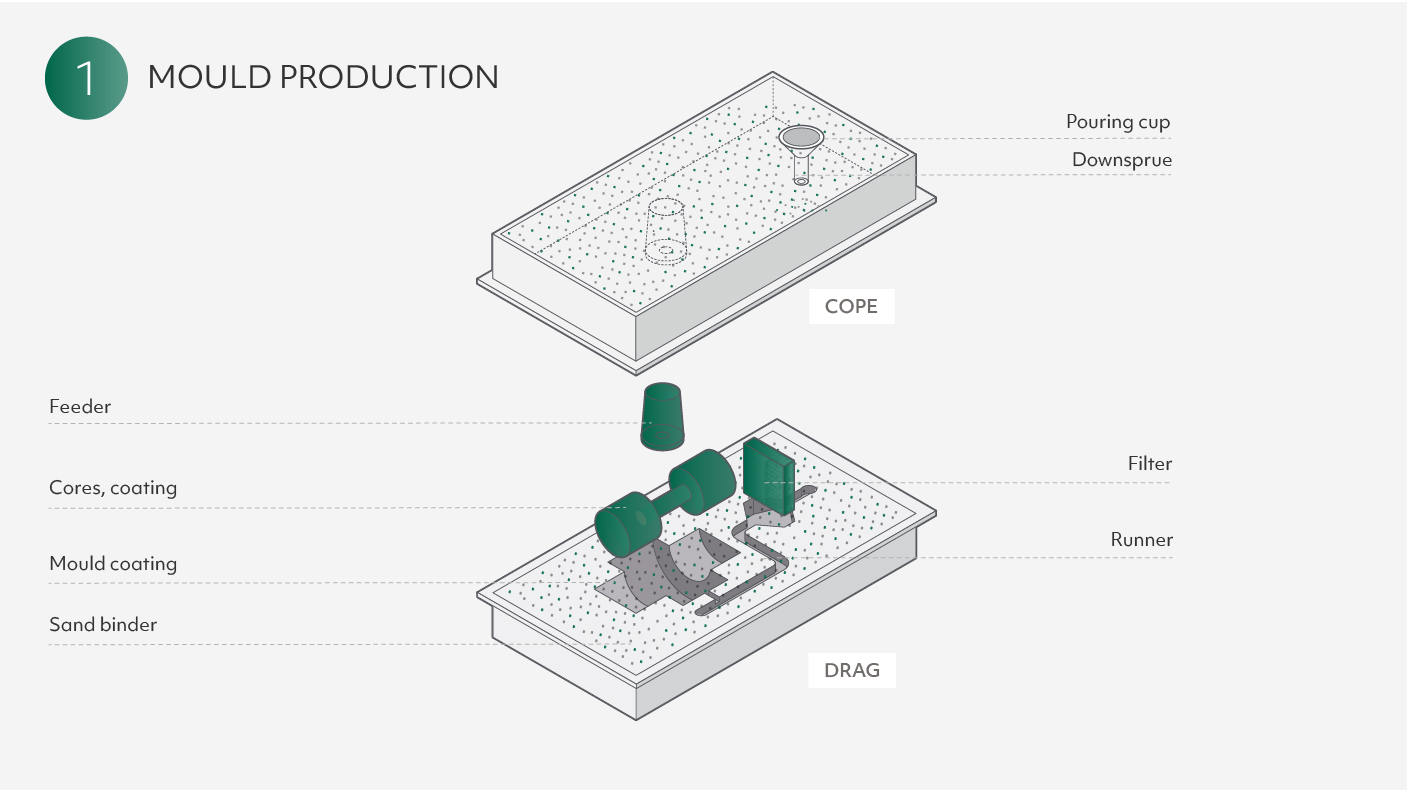

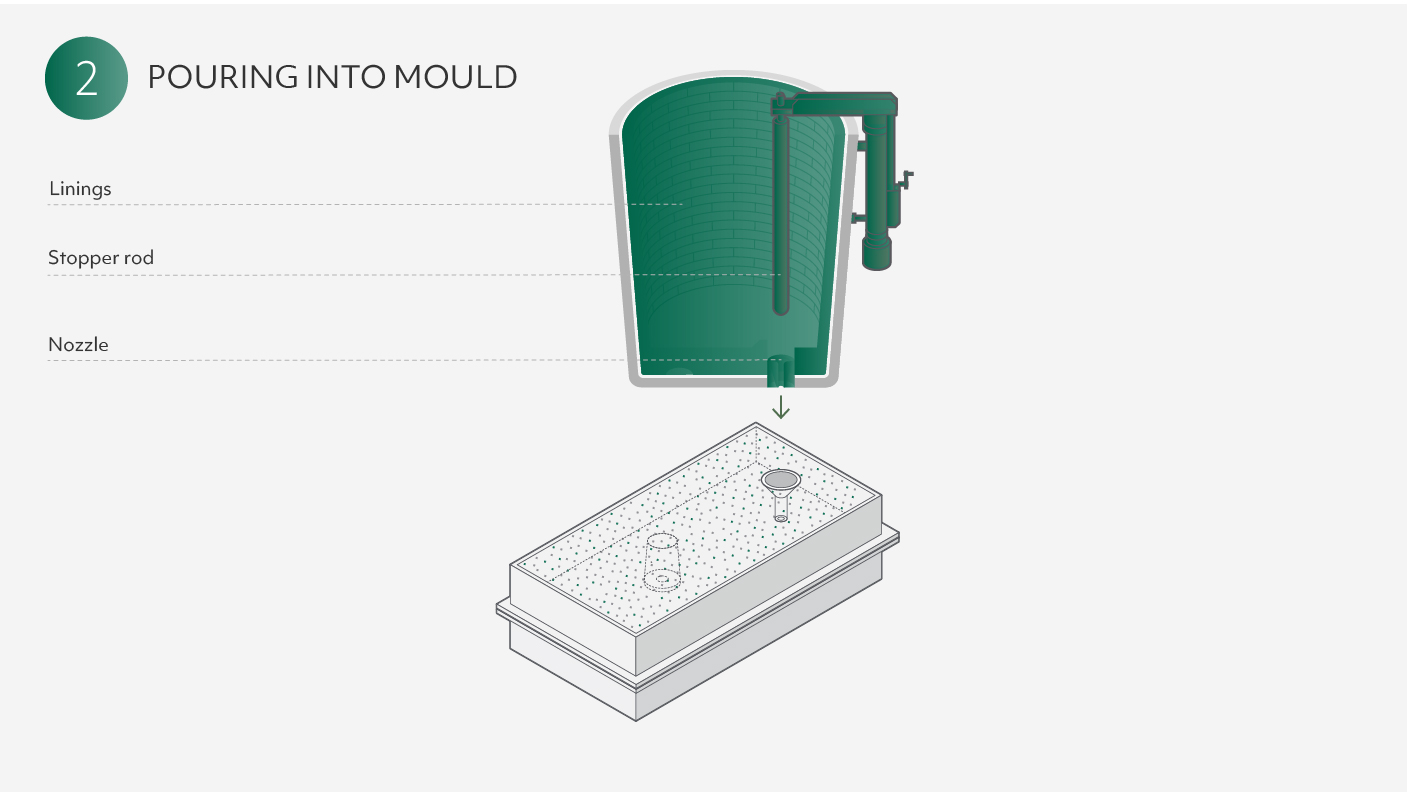

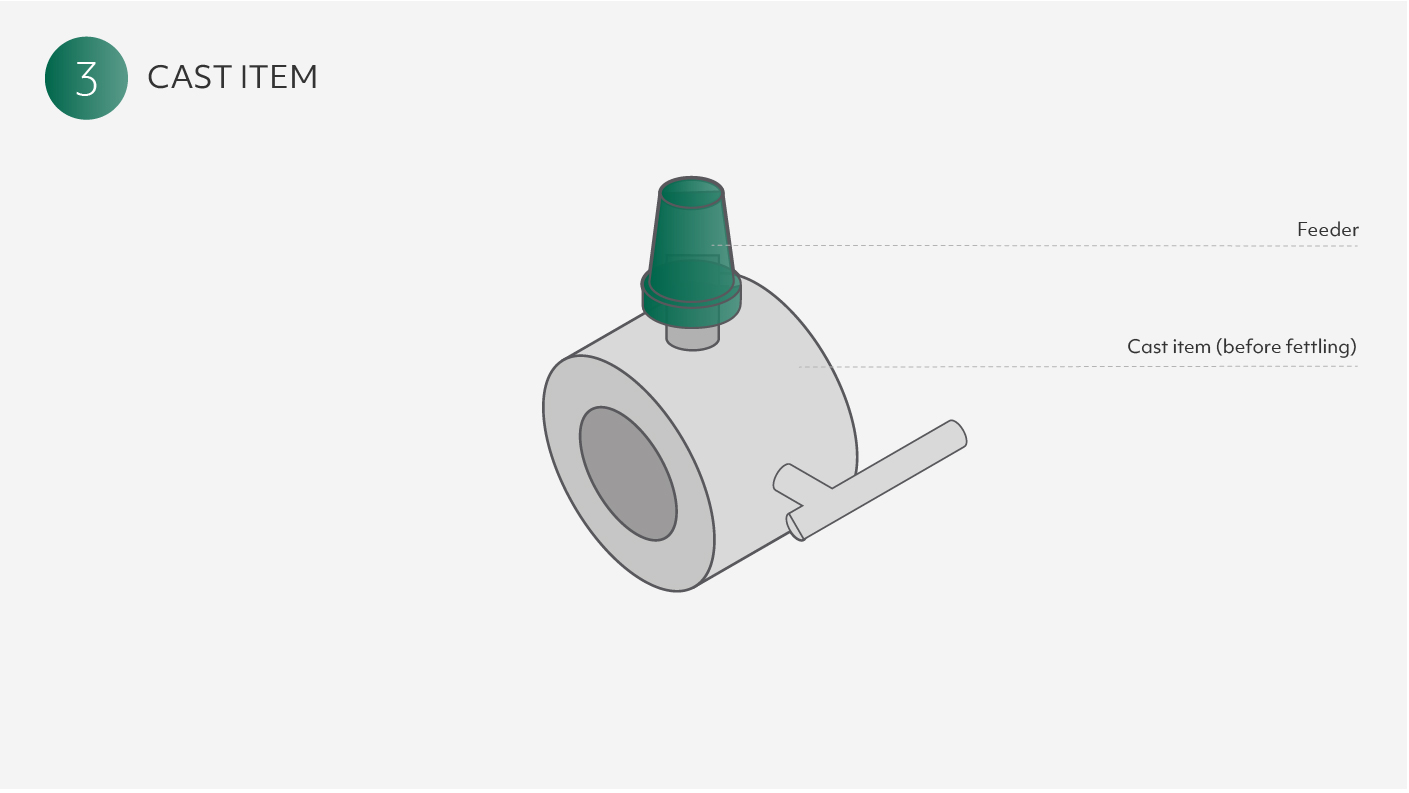

The conditioning of molten metal, the nature of the mould used and, especially, the design of the way in which metal flows into the mould are key parameters in a foundry, determining both the quality of the finished castings and the labour, energy and metal usage efficiency of the foundry.

Vesuvius’ products and services to foundries contribute significantly to improved product quality and yield. Foundry customers are evolving towards more sophisticated and complex castings with increased requirements for cleaner and lighter metal, resulting in a greater need for Vesuvius’ products.